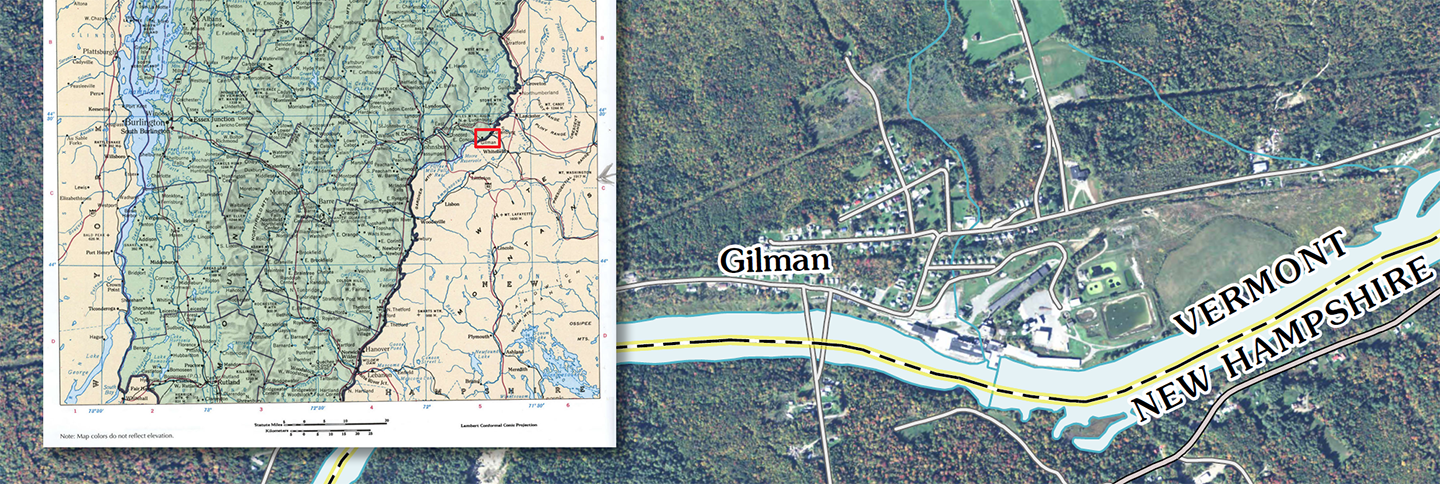

Gilman, VT

The history of a quiet mill town on the banks of the Connecticut river in the scenic "Northeast Kingdom" of Vermont.

Expanding Power Needs

During the early 1930's, two more generators were installed on the end of the line shafts for the water wheels that had been used earlier to power the groundwood grindstones. These generators, plus a steam turbine in the power house, increased the the electrical capacity for the mill and the village significantly.

A group of Gilman gentlemen in front of the Gilman hotel in the 1930's.

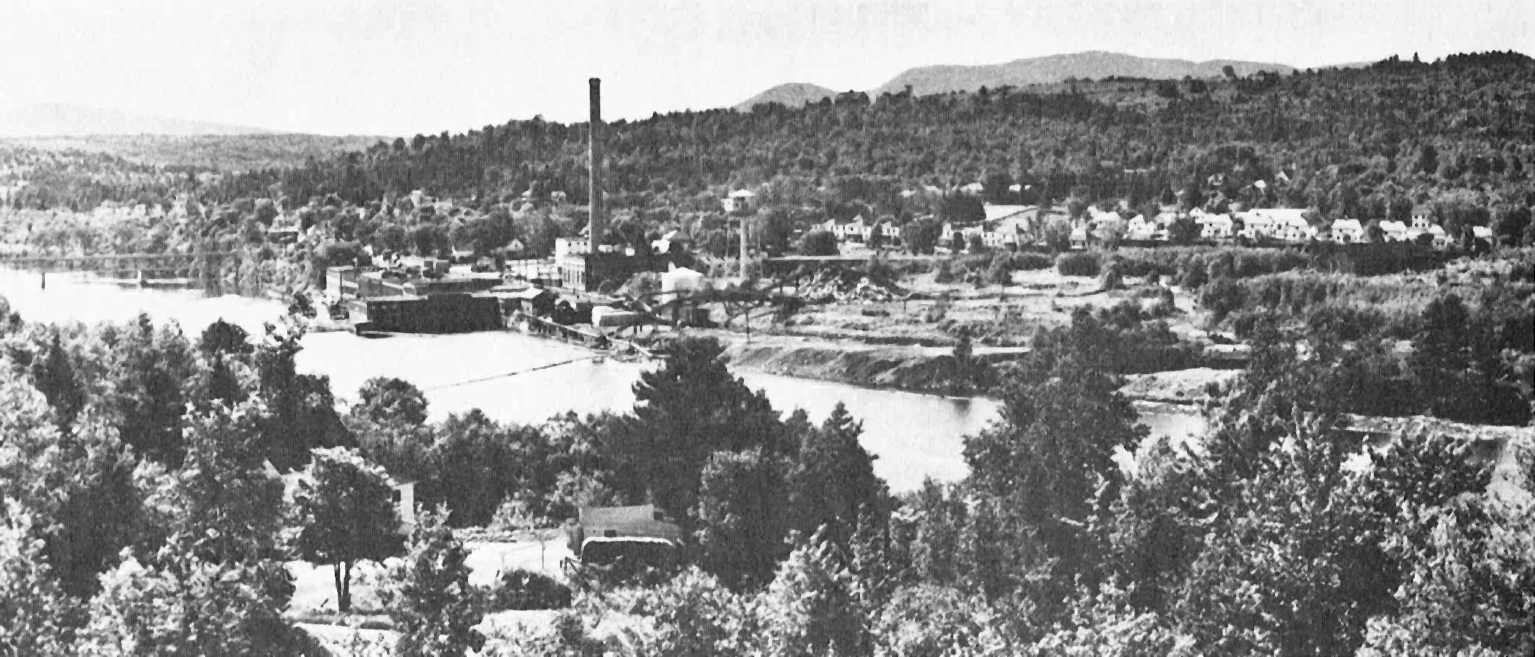

A view of the village of Gilman in the 1930's from across the river in Dalton, NH.

World War 2

In 1941 a new power contract was entered into with teh New England Power Company and a dedicated line was run from the Commerford Dam to Gilman to increase power supply reliability. From 1941 to 1946, the groundwood pulp mill saw renewed activity because of the wartime shortage of pulp from overseas and some of the groundwood was used for gummed tape filler. Once the war was over, the pulp mill shut down permanently.

After the Second World War, an addition was made to the gummed tape department and an asphalt laminating department was started. In the meantime, the original grocery bag department had been phased out in the early 1930's with the growth of the Kraft bag department. The original Milletts' department had experienced rapid growth and now became known as the Cellucord Corporation with a new branch starting up in Richmond, Vermont. At its peak during the war years and shortly thereafter, the Gilman mill employed approximately 1200 people.

A picture of buses parked outside the mill in the 1940's.

A Rough Decline

In the 1950's, the Kraft bag and gummed tape departments were gradually dismantled and moved to Gilman Paper Company's new mill in St. Mary's, Georgia, to take advantage of the lower cost of producing pulp from Southern pine. In 1960, the Cellucord Corporation closed its Gilman department and moved the balance to Winooski, Vermont. The asphalt laminating department had been converted over to wax laminating and that was also gradually phased out in the early 1960's.

The main office personnel in 1952: Larry Newman, Bucky McMann, Blanche Flynn, Grace Smith, and Judy Young.

Fine Paper Production

The decade of the 1960's became the third crucial period in the history of the Gilman Mill. A decision was made to upgrade the mill to produce fine printing papers. A water treatment plant was built and major improvements were made in the pulp preparation department and on No. 2 paper machine in 1961. The remainder of the gummed tape department was changed over to produce adding machine and cash register rolls. Sheeting equipment was purchased and installed in the old bag mill.

Becoming a producer of fine papers in a sluggish, highly competitive market place proved to be a difficult task. Failures coupled with three strikes; the last one causing a seven month shutdown in 1963-64, made the future appear rather bleak. However, after the startup in 1964, the situation slowly improved.

A small ski slope operated on Baptist Hill Road in Gilman from 1963-1981. You can see the warming hut at the top here.

The Death of Charles Gilman

After the death of Isaac Gilman in 1944, his son, Charles Gilman, became the Chief Executive Officer and he kept a keen interest in the Gilman mill right up until his death in 1967. At this point, another major change in direction occurred. Howard Gilman and Charles Gilman Jr., grandsons of Isaac Gilman, decided to consolidate the efforts of Gilman Paper Company on the St. Mary's, Georgia plant.

Georgia-Pacific

The Gilman mill was sold to the Georgia-Pacific Corporation on November 13, 1967 and became part of the Northeast Division under the direction of Robert Schumacher as divisional vice president. A new sense of direction and a new period of growth and improvement began. The steam plant was converted over from coal-fired to oil-fired boilers and many improvements were made throughout the paper mill. The mill began to reach some measure of success in producing and converting opaque offset printing papers. In 1967, a program to develop a base sheet for check paper to supply another division of Georgia-Pacific was undertaken. Eventually this program succeeded and the Whitefield Plant, as the Gilman Mill became known, entered the 1970's as a producer of fine opaque printing papers and specialty technical grades. The last vestiges of the old days were severed when No. 1 paper machine was shutdown in June of 1969, after 68 years of service.

An image from the 1966 Gilman Winter Carnival.