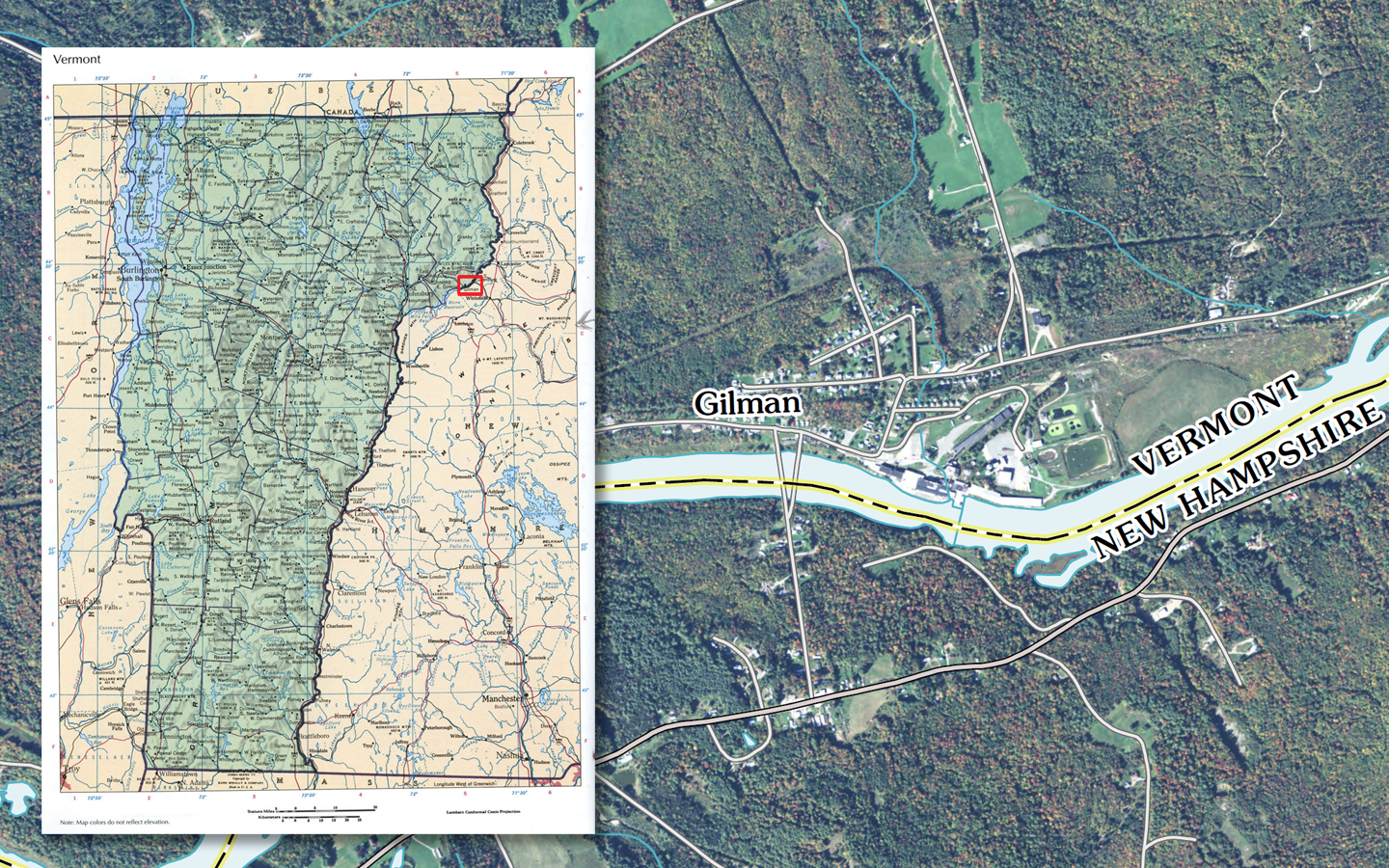

Gilman, VT

The history of a quiet mill town on the banks of the Connecticut river in the scenic "Northeast Kingdom" of Vermont.

In the late Nineteenth Century the village of Gilman, Vermont was farmland owned by Stephen Thompson. As recorded in the Town of Lunenburg registry of deeds, he sold this property to Jack Perry in 1880.

Dalton Power Company

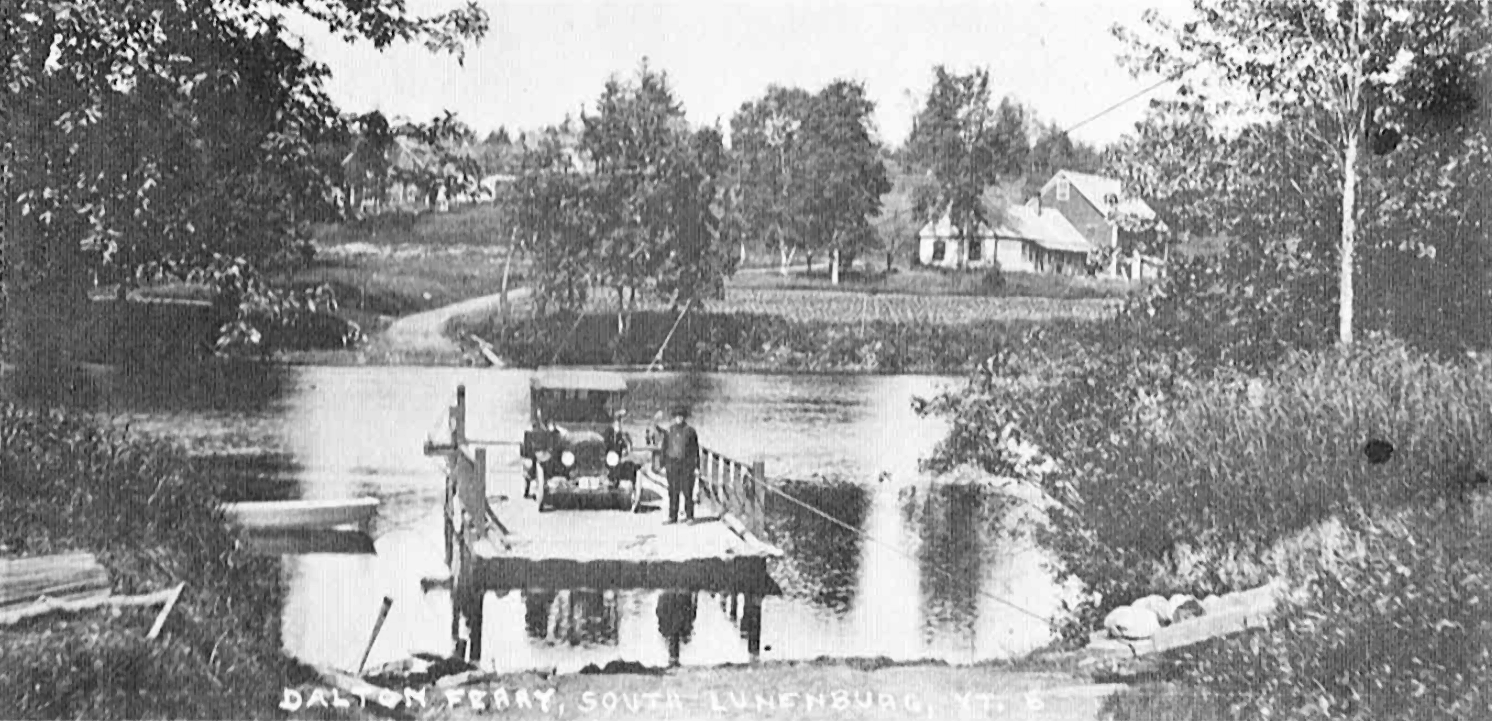

In 1896 the Dalton Power Company purchased this land from Jack Perry with the intent of building a dam and a pulp mill for paper production. The Dalton Power Company applied for its charter at the Coos County Court House in Lancaster, New Hampshire and then proceeded to acquire woodlands for a dependable supply of wood pulp for the mill. A number of large land holdings were purchased on both sides of the Connecticut River between 1897 and 1900 including one large holding owned by George Fitzgerald of 2960 acres in the Guildhall-Bloomfield area. It is believed that Mr. Fitzgerald was a senator in the Massachusetts State Legislature and that he was an important stockholder in the Dalton Power Company. At some time during this period, he is reported to have stayed with Charlie Balch near the South Lunenburg ferry crossing. Charlie Balch was the great grandfather of Gardner Balch, Jr. who worked in the mill's Electrical and Instruments department in the 1990's.

A picture of the South Lunenburg ferry. This picture was taken in the 1930's.

Dalton Paper Mills

In 1899 and 1900, the Dalton Power Company is listed as paying taxes on buildings and 100 acres of land on lots 47 and 48, but the plant itself was tax exempt until 1904. It is believed that the original dam and pulp mill were swept away during high water sometime during this period, but we have no evidence of this. In 1901, the original No. 1 paper machine was installed. In 1902, the Dalton Power Company leased the dam and the pulp and paper mill for a period of ninety-nine years to Dalton Paper Mills, a corporation based in Maine. In 1905, the Dalton Paper Mills paid taxes on six cottages, a hotel, an office, and ice house, a pulp mill, and a paper mill. There were no major changes through 1909.

During these early days, softwood pulp was driven down the Connecticut River during high water periods. The pulp was collected at the dam and either poled into the wood room directly or carried up to a pulp pile behind the mill. The pulp was debarked in a debarking drum turned by water wheels and fed into large stone grinders which ground it down into a course fiber composition called groundwood. Some of these granite stones still remain on the mill site. The groundwood was then used on No. 1 paper machine to manufacture newsprint. The Boston Post was one of the most important newsprint customers in those days.